QUALITY.

ENGINEERED.

SOLUTIONS.

We Are Pump People

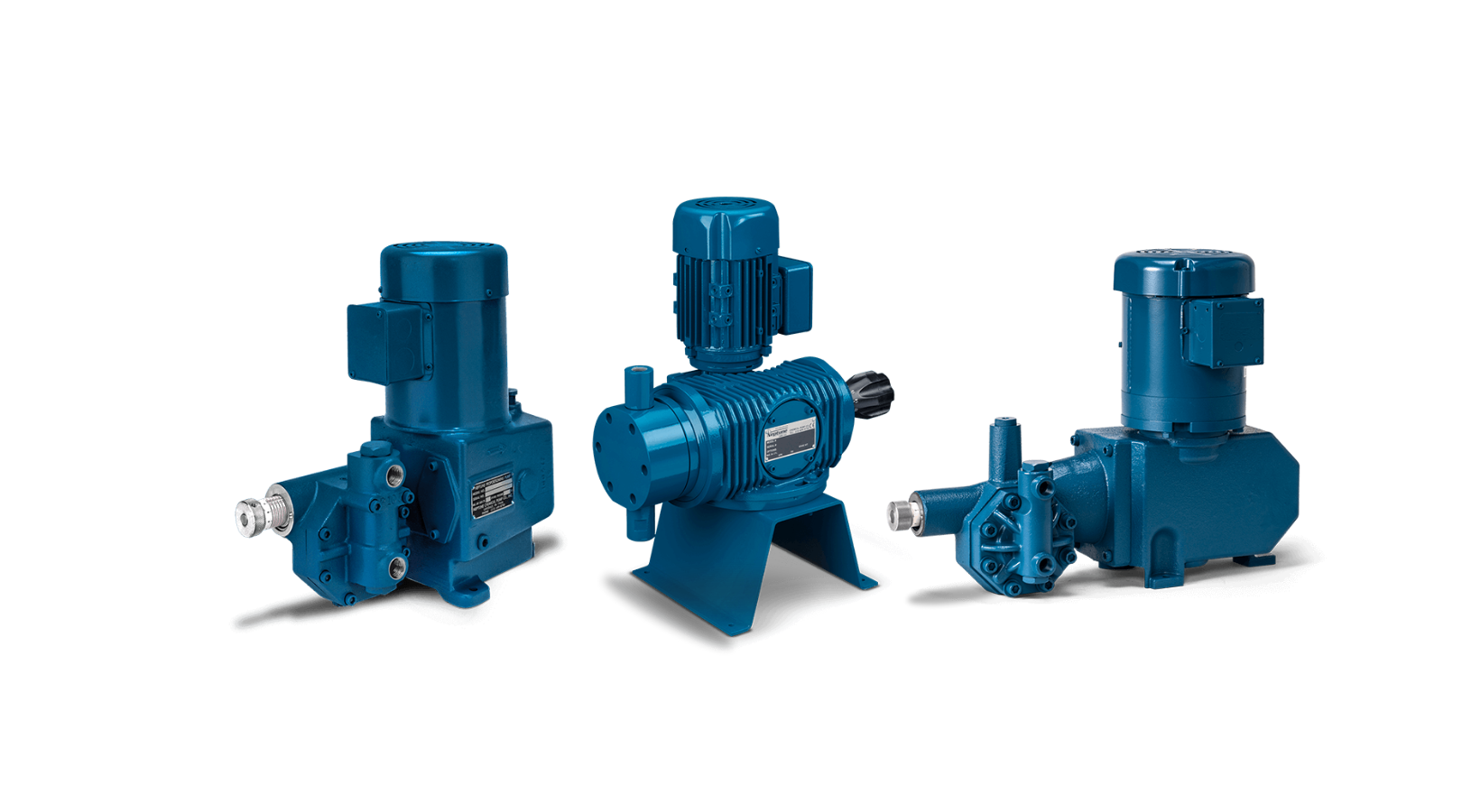

At Hagler Process, we prioritize your success by offering tailored solutions. As a trusted pump and process equipment distributor with years of industry experience, we source top-notch products from reputable manufacturers, ensuring peak performance and durability. Whether you require industrial pumps, valves, controls, or other process equipment, we provide a broad selection of reliable options. Our committed team ensures a personalized customer experience and seamless product integration to meet your specific needs.

Read More Read more about Hagler's Product Line

Products

Services

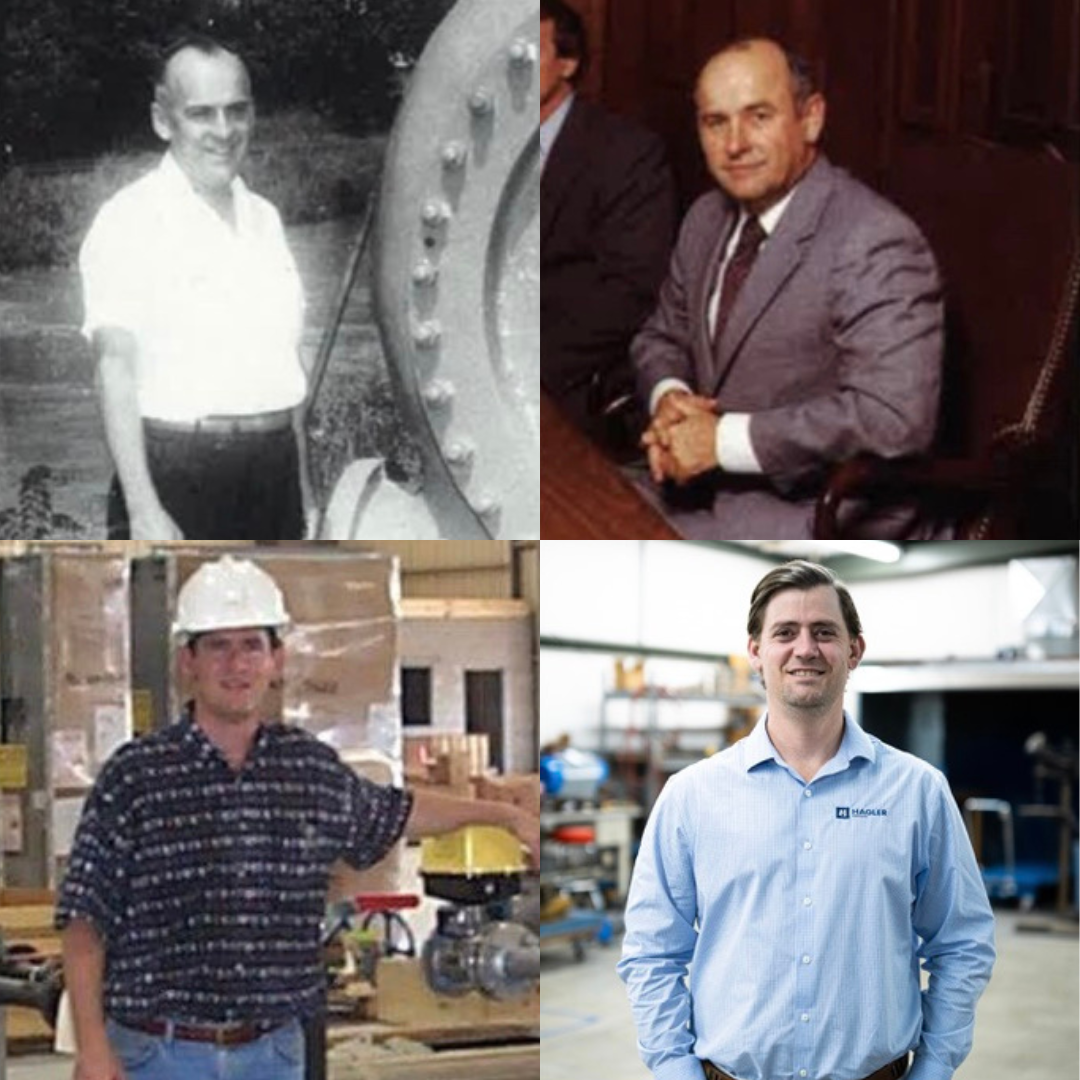

Hagler History

Manufacturers

Streamlining Solutions for Four Generations

The Hagler legacy has spanned over 70 years in the pump industry delivering excellence and dedication, serving diverse markets and prioritizing customer needs. As a family owned business, we value strong, enduring relationships with our customers, focusing on understanding your challenges and goals. More than just a distributor, we are your trusted partner, committed to delivering solutions that enhance your success. Our dedication to quality is unwavering.

Read More Read more about us

Quality

Quality is at the heart of everything we do. Our commitment to delivering industrial solutions and reliable equipment that ensure safety and customer satisfaction is of the highest importance to our team.

Engineered

Engineered is not just a term; it's our philosophy. Engineering isn't just a skill; it's our guiding principle. We are committed to excellence, ensuring that every project we undertake embodies the highest standards of precision.

Solutions

We are driven to innovate and engineer cutting-edge solutions that address the unique challenges of our industry. We pride ourselves on delivering tailored industrial solutions that empower our clients to optimize their processes.

Company News

Are you ready to optimize your system’s performance?

Contact us now and let us help you find the perfect solution for your needs. Whether you have questions about our products, are looking for a custom skid, or have a piece of equipment you need repaired, our team is here to assist you. Your success is our priority, and we're excited to collaborate with you to achieve your industrial goals.